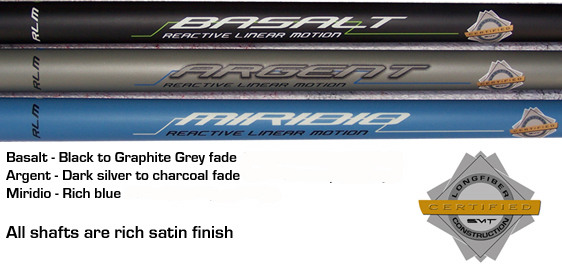

Basalt-46", 69g, 3.4 torque. Retail-$79/Hobbyist-$62/R, S, X flex, please order below

Argent-46", 78g, 3.5 torque. Retail-$69/Hobbyist-$54/R, S, X flex, please order below

Miridio-46", 59g, 4.5 torque. Retail-$89/Hobbyist-$70/

A, R, S, X Flex. Please order below:

Questions/help choosing shaft here

The RLM Story

Having been a guest at several different shaft factories overseas and spending a few days each year watching how they produce shafts, it became curious to me why there were more than a few shafts made with the same mandrel. The answer is a simple one though. Shaft mandrels cost a lot of money.

In other words…the playing characteristics of so many shafts are determined by the sanding procedure of the shaft tip and shaft butt sections that were programmed into the computer.

Looking at these sanded shafts under a microscope there were so many graphite fibers that were compromised or destroyed during this sanding process. I came to the conclusion that if a graphite fiber has been cut or weakened during the manufacturing process, there is no way that the fiber was doing anything for you in the way of transferring the energy to the clubhead. The only thing left to the structural integrity of the shaft, is the epoxy resin that binds all of the graphite material together. That fact is clearly evident. Why would manufacturers choose more expensive raw materials only to have them cut apart by the sanding process?

This simply does not seem to me, like the best way to produce a product, a product that we all pretty much agree plays such an important role in our games… well, it evidently is "good enough" for some, but you had better stop talking about the playing characteristics of the graphite material that you are using, or the expense of these same fibers, while producing shafts in this manner. The fibers are cut or compromised, there is no direct transfer of energy through the graphite fiber material after is has been severed. The only transfer of power is through an epoxy like material that is very similar to the same epoxy that holds the head to the shaft.

Through my research, I have found that many of the shafts currently on the market only contain roughly 35% of the original fibers intact. This got me thinking of what the golfer, any golfer, needs to be more efficient when trying to produce a stroke or moreover, to produce a repeating stroke. The answer was pretty plain to me…… More graphite fibers that are left intact during the manufacturing process, should produce a better feel and thusly better results.

I then started to think about the market that I wanted to approach with my shaft line. It was not the Tour Professional, as the money needed to get OEM companies to feel comfortable enough with my product to offer it as an "upgrade" is simply too expensive. If I chose to deal directly with the Touring Professional, I would have to give away so much product to so many players that the end cost of my shafts would be far too costly for the average player to handle. Besides that, I never understood why so many golfers, seem so determined to play the same products as they see their heroes playing on Sunday afternoon. I mean, the only correlation between the average handicap player and the Touring Pro is that we both play 18 holes before we turn in a scorecard. Who really cares what works for them? I wanted to get a product into the hands of the guys and gals that are trying to win their $2 Nassau for bragging rights at the nineteenth hole.

I thought about the sport of longdrive, as my company is often brought up in the same breath as that sport. But the same thing is happening there. While fun to watch, there are not a lot of golfers out there that feel that they can relate to the huge swings and grunting sounds seen on ESPN each Christmas Day by the world's longest hitters.

I went back to my studies and confirmed that the average score of a daily golfer in America is actually about a 93. This was actually very hard for me to believe. I wanted to think it to be a much lower number. But these are same people that I hear from day in and day out, and my dealer base hears from on a daily basis. These golfers are my actual customers. What these golfers need is playability. Playability is often confused for whatever reason with feel, or players "perception" of feel. Perception of playability often is a function of out of pocket cost for the product as well. I have listened to so many customers make comments such as… "For $200.00 this shaft should play noticeably better than what came in my club in the first place". If it does not make a noticeable difference, confidence is lost, and the customers enjoyment of this expensive game is compromised at the same time.

It was obvious that I needed to come up with a shaft that was consistent, a shaft that could be used and enjoyed by every single golfer that my clubmakers would run across. A shaft that would help the player to feel the shot and to reward them for shots that were not perfect. I wanted to have the shafts be affordable to the modern day player, with all of the pressures put on their expendable income by the society that we live in, and of course, it would have to be a shaft that could stand behind with the SMT Golf Lifetime Warranty, a shaft that would not hit them any harder than necessary in their pocketbook. I need people to play more golf, and I figured that the best way to do that was to make sure that they could afford to play more golf.

I came up with the name RLM, which stands for Reactive Linear Motion, a phrase often used to define torque. A word that is often used by golfers and clubmakers, but a word that is rarely understood, and certainly a word that is not regulated in this sport. I wanted to somehow get back to common sense. I wanted to get shafts back to actually using the materials that we put into them. In this case, the material is graphite. I knew that the shaft industry, in fact he entire golf club industry is plagued by the fact that each and every single clubhead or shaft is in effect, hand made. Welding and finishing of clubheads and sanding or wrapping of shafts in the case of sheet wrapped or table rolled shafts. It came down to realizing that the more that the human being touches the product, the better chance it has of being out of spec.

After talking with the real designers at the factory about my feelings and ideas, we decided upon a shaft design that really, simply removes much of the human element from the process. The RLM Series shafts are made from what I am referring to as "Long Fiber Technology". The shafts are filament wound, as I didn't want there to be a spine in the shafts and that I am truly convinced that filament wound shafts are far superior in their overall performance to their table rolled cousins. While I am sure to get opinions that are not similar to mine, I truly feel they are better and more consistent.

"Long Fiber Technology" is simply what it states. The fibers that go into the creation of these shafts are simply handled or processed less than traditional or current shafts that you will find on the market. This was achieved by focusing not on the finished product, but on the mandrel that was used to wind the fibers around. Starting from the very beginning seemed right to me. Getting back to the beginning of this story, I felt that there are simply too many shafts being produced that are simply sanded to final spec.

The RLM Shafts , utilizing Long Fiber Technology are made to a constant taper from butt to tip. They require very little sanding to produce and the feel of a lively tip is very much favored by amateur golfers of all levels. In fact, the RLM Shafts that I have helped to create actually have approximately 95% of the fibers still intact. What this means is that the energy you deliver to the ball through that shaft is deployed through actual graphite fibers, instead of epoxy resins that you are paying for. The feel that you receive back from impact is also brought to you through the same full strand graphite fibers. It simply seemed to be common sense to me.

The RLM Series of shafts has a lively tip, while some might have a theory against that idea, my theory is that I would never choose a fishing rod that didn't have a more lively tip. Centrifugal force keeps everything straight and solid.

RLM shafts with Long Fiber Technology simply feel good. They simply produce a shot that is easier to get in the air, and the longer the ball is in the air, the further it should go. They are affordable, come with an unbelievable lifetime warranty against breakage and are made to accommodate the largest variety of golfer's individual swings. They are coming to help you to enjoy the game of golf a bit more, and at a price that will not break the bank. The RLM shafts are surely worth looking into, and I hope that you enjoy the product.

Questions/help choosing shaft here