|

Product Profile

|

Star Grips

Not all grips are created equal.

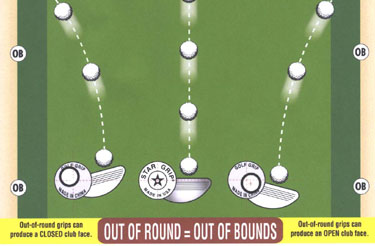

Out of round is out of bounds.

There are numerous ways

to evaluate the quality of a golf grip and we believe there are

3 major areas that need to be considered. By adopting our seamless

true round molding technology we were able to make a quantum

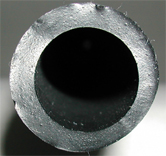

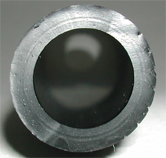

leap forward. The pictures above show cutout sections of two

grips. The picture on the left is a cutout from one of the "World

Leaders" and the picture on the right is a cutout of a Star

Grip, clearly showing the advantages of our Seamless True Round

Technology. Out of round is out of bounds.

FIRST and most important item of all has to do with

the concentricity of the finished product. If the grip is out

of round and it is placed on a shaft that is straight, a condition

is created that is exactly the same as having a bent shaft. We

have seen out of round conditions of nearly 1/16th (.0625) of

an inch. We do not believe that is a desirable condition on any

club and must conclude if you are out of round...you are out

of bounds. Our Seamless True Round Technology is the only tooling

innovation in grip manufacturing in 50 years and automatically

minimizes the out of round condition that exists with the spit

cavity double reject line process.

SECOND is the weight consistent. Over the years we have

evaluated thousands of golf grips and found astounding variations

in weight. It is not uncommon to find a 12% variation or a total

of 6 grams per grip on a batch of 50-gram grips. This variation

can mean up to 2 full swing weights between clubs. We continue

to strive for the perfect grip and will eventually get there,

but have managed to get our total variation to a little over

1 gram. +/- 0.6g. One of the secrets to our success is the seam

less true round tooling. We have worked hard on the weight issue

to improve the quality and improve production efficiencies via

SPC. i.e., improved quality drives costs down. In the injection

molding process, a variation in the size/volume of the cavities

guarantees production problems that do nothing but increase costs.

Click here for SPC.

THIRD is the rubber compound itself. The feel... is

it tacky and supple? Does it stay that way over time... even

several seasons? Or does it get hard and slick quickly? Does

it play well in all weather conditions? Is it difficult to install?

Does it unravel and absorb moisture? Is it durable and long lasting

or is it a wrapped thermoplastic substitute for rubber that is

extremely susceptible to attack by Ozone and UV? Worse is a low

grade SBR and natural regrind used? It is not complicated. A

premium quality, rubber rich formula cost more and from our way

of thinking, it's worth more. We think you will agree. Put a

Star Grip on one of your clubs and you will have all the answers

to the questions above. Tired of your grips getting hard and

slick? Star Grips stay tacky and supple.

We believe that most Americans

would prefer to purchase products made in the USA, but nowadays

it is not easy to find Made In The USA on anything. In the 1970's,

the American industrial complex had a planned obsolescence philosophy

and an attitude that if you didn't like it, it was just too bad.

A statistician by the name of Dr. W. Edwards Deming came along

with a method that he claimed would improve productivity, reduce

costs and most important of all dramatically improve quality.

It was called Statistical Process Control, or SPC. The concept,

like so many good ideas, is extremely simple: In a manufacturing

process, step by step, eliminate all of the variables and do

things over and over, exactly the same way, time after time.

With everyone in the supply chain, from the raw material supplier

to the finished product producer embracing SPC, automatically

rejects are reduced, costs go down and the quality improves.

Demming tried to interest the American automobile industry in

his method without success. At the time they enjoyed a 70-75%

market share. Demming then approached the Japanese automotive

industry and they immediately understood the long term benefits

and adopted the concept. The rest, as they say, is history. Americans

prefer quality above all else and we are willing to pay for it.

The U.S. auto industry lost nearly half of the market share and

in the end realized their mistake and adopted SPC. Golf is a

game of fractions of an inch and the last time we looked, a club

had 3 components, a grip, a shaft and a head. If quality or consistency

is compromised on any of these components, obviously, performance

will be effected adversely. Long term, we believe that a superior

product that enhances the performance of any club will make Star

Grip a winner.

|